MechaBits GimBal - Sony a6300

While everyone else was making carbon fiber gimbals which seemed to have far too many parts and looked a little cumbersome, great for drones but not so good for single handed op.

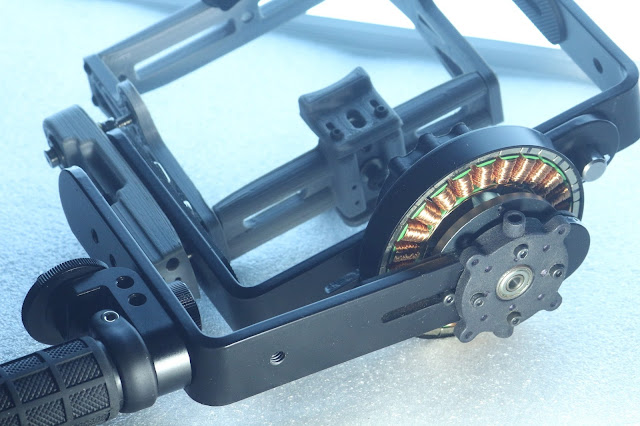

I Decided I needed something more compact, handheld, mostly metal & modular if possible

At the time I tried out a number of gimbal configurations, and slowly reduced the part count, a simple idea using cheap Metal L-brackets, even though they are a little springy they can be doubled up(though a new design option to replace with more Arca's has more advantages), dovetails for adjustments, the new round arca clamps are ideal to fix to motor, Arca's are stronger & look much better, the nodal arca's a bit pricey but better than getting a part machined.

Soon after designing this, other similarly arranged handheld gimbals started appearing, now all have motors with encoders, some have a better load capability with relatively small motors compared to the 8017, some even now come with an iso arm or 2 like my other early design, the things you can do when you have the machines to cut metal :(

I was never sure the printed parts would be up to the job, as the camera load is at the limits of some other gimbals, the first part for this gimbal I had printed by Shapeways, I was quite happy with it, strong and still in use, it's on the back of the 8017 motor, but the latest part I printed in PLA to attach the L-Brackets to the motor seems strong enough for the job. I was hoping the part would need no further mods but soon after printing I found an article on modding the 8017, so if I want to mod the 8017 to take magnet & encoder, or the wider arca plate instead of the L-Brackets I will have to design another part, though I havent loaded the camera & roll cage on there yet. Mulling over a few options of motors with encoders, and mounting options, probably round arca clamps but there 2 sizes & other variations, though the one with slots is almost twice the price of another with 2 holes.I might just be able to finish this gimbal without printing anymore parts.

Still need to install motor, will flip the arca plate and use a double arca clamp to attach motor, so that I can slide motor for balance, in the same way handle can move, and be upgraded for 3rd axis

Waiting for more parts to arrive, I have a little time to test out a few ideas, different bearing arrangements for axis if I decided to support axis alternate ways, and playing with the idea of belt driven arrangements, I doubt any will make it to final design, maybe one will, but they might be useful for other things in the future.

Comments

Post a Comment