Make & Mix Machines Modules

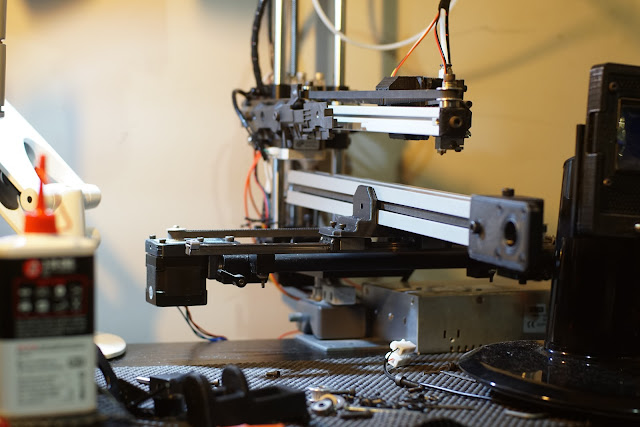

Workbench was getting a little overcrowded, Machine's & Parts all over the place, time to merge some machines. Of the machines not in use & under construction, there are four motion axis mechanisms using dual 12mm rods, not all on the same machine, i'd like to combine/consolidate them all into one machine, it's either that or order new parts? 12mm Rods always handy to have but with 9x IKO 300mm Linear Rails arriving any day, I have to figure out how I will distribute the parts to make the most of them... One use for the Linear Rails will be for a new XY Stage/Bed, 2x IKO Rails supporting the 3030 Beam/Bed/Axis (using the part in the images above, need a second carriage for the other rail & a belt/drive block, decided to reprint the Motor mount & idler for the new belt arrangement, In a Single Rail setup was all that was needed but the belt path was a little convoluted, there where 2 idlers attached to the end of the rail, which had to use the gt2 pulleys with bearings inside, replacing those with proper pulley in better bearing holder, if I use 2x Rails to support the beam I can drive it from the center, saving parts, and improving things has to be a good idea. minimizing the parts needed for the inline belt drive, now in the center of the Black rods, utilizing the metal parts better...but already thinking about replacing the mechanism i'm building ie the belt drive version, thinking about an alternate using lead or ball screws, just to explore the design/options/ or an alternate version with a piece of T-Slot as the hold down table, a way to quickly swap from normal 3D Printer Build Surface to T-Slot on the horizon. When thats done I wont need the X axis arm on that printer, as it's a 9mm rail on 2020... a small light arrangement but was in need upgrading the arm to incorporate the better features from the other arms(Rigidity & Joint to Z). I know the XY table on this arrangement will need the motion restricting(until I combine with an alternate Z/Tool) as the beams are 300mm and I dont want a build plate hitting anything, so once its all setup I can figure out a design for an ideal stage/workbed then maybe a way to cover the guides & screws...lots of options to explore...the fun part. DO I tear Down Godzilla use the 12mm rail mechanism in something else, and use the heavy aluminium plates as Gantry Support Cheeks? Inside the Cube? On the 12mm Rods & Extra Wide bearings? While I mull over that, I scan the rest of the machines & parts for a way to mate & merge them, & figure out what are the catalyst parts needed to make that happen. This roll of filament isnt lasting quite as long as the last one, wondering if they only supplied .75KG, need to order more but want a darker black, as this is almost transparent when it leaves extruder...needs more pigment, so in the search for a decent Matt Black i'll try something different next time.

Combining A few more Concepts into each other, helps to spark other ideas & part postulation.

Comments

Post a Comment